Blowing In-mould Labels

Links Click here

In addition to saving the time and costs for traditional coated label production, printing and auto-labeling on bottles, this process is helpful for recycling and preventing from imitation. Synthetic paper has excellent characteristics in printing effect, forming operation and cost efficiency and is the best choice for this application. It is especially suitable for printing houses and food manufacturers.

.jpg) Product Grade:

Product Grade:

CVG-98 (primer treatment,medium gloss)

CVG-100 (primer treatment, embossed effect gloss)

CVG-110((primer treatment,medium gloss)

NVP-102 (corona treatment, gloss)

CVY-108(primer treatment,medium orange surface)

| Product Item | Thickness(um) | Process Description | Application | Description |

| CVG-98 CVG-110 CVY-108 |

98 110 108 |

☆Genaral and lithographic and flexo printing,and varnish process after printing ☆Use solvent oil based,water based and uv ink |

Printing,Heat transfer label,Blowing In-mold label |

☆Easy printing,partial varnish effect of printing product, especially the layering display of image detail |

| CVG-100 | 100 | ☆Genaral and lithographic and flexo printing,and varnish process after printing ☆Use solvent oil based,water based and uv ink |

Printing,Heat transfer label,Blowing In-mold label |

☆Easy printing,partial varnish effect of printing product, especially the layering display of image detail

|

| NVP-102 | 102 | ☆UV lithographic and flexo printing,and varnish process after printing | UV Printing,Blowing In-mold label |

☆Easy printing,partial varnish effect of printing product, especially the layering display of image detail |

Advantages of Synthetic Paper :

Advantages of Synthetic Paper :

- Applicable to one-piece PP bottles and HDPE bottles.

- Excellent processing capability and Low cost production.

- It can be recycles together with the containers made of the same material.

- Perfect surface performance.

Applications:

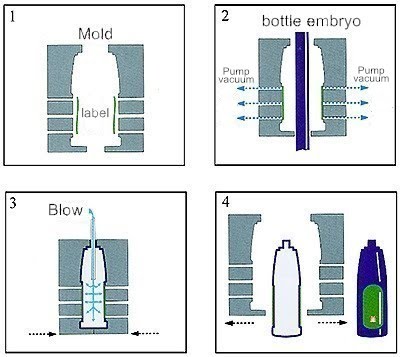

In the current blowing process, putting labels into a mold with a robotic manipulator is commonly used to make one-piece products . In addition to saving the time and costs for traditional coated label production, printing and auto-labeling on bottles, this process is helpful for recycling and preventing from imitation. Synthetic paper has excellent characteristics in printing effect, forming operation and cost efficiency and is the best choice for this application. It is especially suitable for printing houses and food manufacturers.

Refer to the In Mound labeling for Blowing Process as below.

Process:

Process:![]() Physical Propety Table:

Physical Propety Table:

- Attached: CVG-98 Synthetic Paper.pdf

- Attached: CVG-100 Synthetic Paper.pdf

- Attached: NVP-102 Synthetic Paper.pdf

- Attached: CVY-108 Synthetic Paper.pdf

- Attached: CVG-110 Synthetic Paper.pdf

- Attached: Blowing In-mold Labels guide book.pdf